Besides advanced production equipment like W&H cast/blown line and reliable raw materials, we have rigid quality testing and control procedure. It is designed to ensure products’ quality and load stability in the filed to uncover the limitations and unknowns of your products transportation and in-transit environment.

We have exceptionally skilled professionals with 20+ years of experience in the plastic industries who are from Yongjia Group. Combined with our cutting-edge lab facilities, we are capable of conducting intensive and comprehensive real-world tests and simulations to produce fact driven solutions to help you achieve optimum load stability and safety.

According to customers’ exact needs like application scenarios, specification, and so on, we will fulfill customers’ needs through the recommendation of optimum wrapping configurations, right use of packaging material, and other industrial best practices to reduce much cost on packaging materials and transportation damage, increase the stability of cargo transportation and storage , and realize environment and user friendliness which can avoid troublesome claims and cycle easily.

1.Rigid Quality Testing & Control Procedure

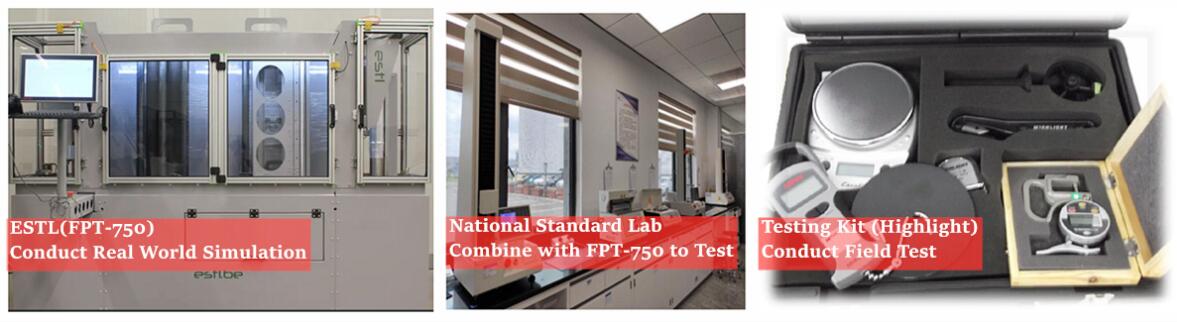

We adopt all-checking and spot-checking together to control quality. We use advanced ESTL (FPT-750 )to do all-checking on some performance of nano stretch film and a national-standard laboratory to do spot-checking as 4 times each day on performance of nano stretch film and FFS resin bags. Our Technical personnel work 24-hour to control quality to use FPT-750 and national-standard laboratory.

2.Advanced Quality Testing Equipment

◎FPT-750(ESTL)

Belgium Imported advanced equipment can simulate the real load condition to test the stretch properties, puncture resistance, containment force,etc..

◎National-standard Laboratory

A national-standard laboratory can test transparency, lab’s stretch properties,and etc..

◎Testing Kit (Highlight)

Until now,we have conducted 40+ field tests for customers which covers 7 industries .

Copyright @ 2019 Huangshan Yuandian New Material Technology Co., Ltd.

皖ICP备19008353号